Shot blasting, a mechanical surface treatment process, shares similarities with sandblasting and peening. It is a cold treatment process, divided into shot blasting cleaning and shot blasting strengthening. Shot blasting cleaning, as the name suggests, aims to remove surface impurities such as oxidized skin, enhancing the appearance quality. Shot blasting strengthening involves using high-speed projectiles (60-110m/s) to continuously impact the surface of the strengthened workpiece, inducing changes in the target material's surface and subsurface (0.10-0.85mm) during cyclic deformation:

Modification of microstructure.

Introduction of residual compressive stress in the non-uniformly deformed outer layer and residual tensile stress in the inner layer.

Changes in surface roughness (RaRz).

Impact: It enhances material/part fatigue fracture resistance, prevents fatigue failure, and improves fatigue life, plastic deformation versus brittle fracture.

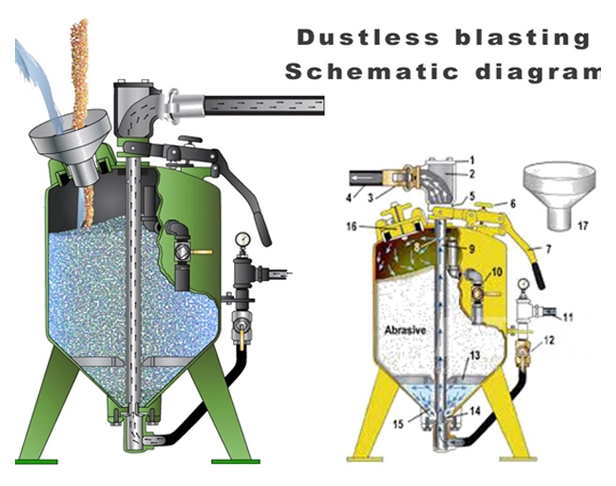

The Principles of Shot Blasting Process

Shot blasting involves propelling shot materials (steel shots) onto a work surface at high speeds and specific angles. The high-speed impact of the shots on the work surface, coupled with the combined action of vacuum negative pressure and rebound force from a matching vacuum cleaner, allows the shots to circulate within the equipment. Simultaneously, the vacuum cleaner's airflow cleans and separates the shots and removed impurities, enabling the reuse of the shots. The shot blasting machine is equipped with a dust collector, ensuring dust-free and pollution-free construction, enhancing efficiency while protecting the environment. During operation, controlling shot size, shape, adjusting machine walking speed, and regulating shot projection flow achieve various shot intensities, resulting in different surface treatment effects.

Technical Requirements of Shot Blasting Process

When operating a shot blasting machine, controlling and selecting shot size and shape, adjusting and setting the machine's walking speed, and regulating shot projection flow achieve different shot intensities and, consequently, diverse surface treatment effects. The shot blasting process and equipment, depending on the surface to be treated, are controlled through three parameters to determine the surface condition post-treatment:

Selecting the size and shape of the shots.

Adjusting the machine's walking speed.

Controlling the flow rate of the shots.

These three parameters work in harmony to yield different treatment effects, ensuring the desired surface roughness post-shot blasting. For instance, using S330 steel shots, a flow rate of 10A, treating a C50 concrete surface achieves a roughness of 90. When treating an asphalt surface, it removes oil film while achieving a roughness of 80. For steel plate treatment, it can reach the cleanliness standard of SA3.

Common Shot Blasting Materials

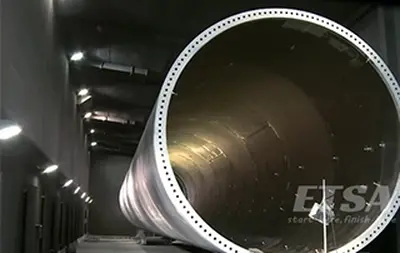

At ETSA, one of leading and professional shot blasting equipment manufacturers, our common shot blasting materials include steel shots, aluminum shots, ceramic micro-powder, steel sand, walnut sand, corn cob, glass beads, resin sand, and plastic sand, among others.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China