In a highly competitive industrial environment, improving production efficiency is key for enterprises to remain competitive. Rotary table shot blasting machines, as an advanced metal surface treatment technology equipment, are gradually becoming an effective assistant in enhancing industrial production efficiency. We will explore the applications and advantages of rotary table shot blasting machines in improving industrial production efficiency from four aspects.

Efficient Processing: Reduced Production Time

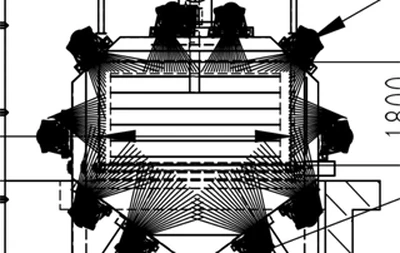

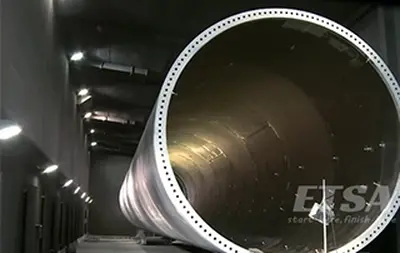

The rotary table shot blasting machine offers high efficiency, significantly shortening the surface treatment time for metal parts. By using a high-speed rotating table and ejected shot media, it achieves uniform cleaning, degreasing, and strengthening of metal surfaces, thereby improving the overall efficiency of the production line. This efficient processing enables companies to complete orders more quickly and meet market demands.

Automated Operation: Lower Labor Costs

The rotary table shot blasting machine employs an automated operating mode, reducing the need for manual intervention. Operators only need to set the parameters, and the machine will automatically handle the surface treatment of metal parts. This not only reduces labor costs but also minimizes the impact of human factors on product quality. Additionally, automated operation decreases the physical strain on operators and enhances workplace safety.

Enhanced Product Quality: Reduced Defect Rates

The rotary table shot blasting machine significantly improves the surface quality and performance of products through cleaning and strengthening of metal surfaces. Treated metal parts have smoother, more even surfaces, stronger coating adhesion, and better corrosion resistance. This not only enhances the overall product quality but also reduces defect rates, saving costs for the company.

Flexible Adaptation: Meeting Diverse Needs

The rotary table shot blasting machine is highly adaptable, capable of handling metal parts of varying materials, shapes, and sizes. Whether dealing with large equipment or small components, efficient surface treatment can be achieved by adjusting the machine's parameters. This flexibility allows companies to quickly adjust their production lines to meet different order requirements, improving production efficiency.

As a high-efficiency metal surface treatment technology, the rotary table shot blasting machine offers significant advantages in enhancing industrial production efficiency. By providing efficient processing, automated operation, improved product quality, and flexible adaptation, it helps companies shorten production cycles, reduce labor costs, enhance product quality, and meet diverse needs. Looking ahead, with ongoing technological advancements and expanding applications, the rotary table shot blasting machine will play an increasingly vital role in industrial production.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China