Autoclaves are essential pieces of equipment in various industries, ranging from medical sterilization to composite manufacturing. But did you know that there are different types of autoclaves designed for specialized applications?

In this comprehensive look, we'll delve into various types of autoclaves, understand their specific functions, and focus on some key applications like carbon fiber autoclaves and autoclave vulcanization rubber processes. If you're in the market, you'll also find this article useful as we will highlight composite autoclave suppliers and share information on small composite autoclaves for sale, featuring the trusted brand ETSA.

1. Medical Autoclaves

Medical autoclaves are crucial for sterilizing surgical instruments, laboratory equipment, and medical waste. These autoclaves often use steam to achieve high temperatures that kill bacteria, viruses, fungi, and spores. Hospitals and clinics primarily use these to ensure that their tools remain uncontaminated. This sterilization process is quick and highly efficient, making the medical autoclave an indispensable part of healthcare settings.

2. Industrial Autoclaves

Industrial autoclaves are designed for large-scale applications. The food industry, aerospace sector, and automotive industry use these autoclaves for various processes. For example, food production facilities use autoclaves to pasteurize food products, ensuring they are free from harmful pathogens. Likewise, the aerospace industry relies on autoclaves to cure composite materials used in aircraft production. For those interested in high-performance materials, the carbon fiber autoclave for sale is particularly noteworthy. The purchase of a quality carbon fiber autoclave can dramatically improve the final product’s strength and durability.

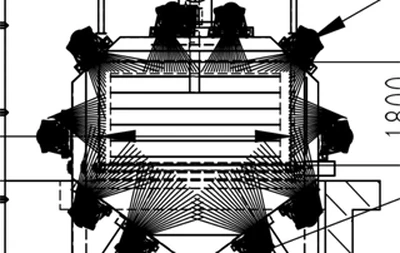

3. Composite Autoclaves

Composite autoclaves are specialized for curing composite materials, such as carbon fiber and fiberglass, which are often used in high-performance products. These autoclaves use high pressure and temperatures to ensure that the composite materials are devoid of imperfections. ETSA is a recognized brand in this space, known for offering efficient and reliable options. If you are a manufacturer looking to invest, you can find small composite autoclave units designed for smaller-scale operations. These compact units offer the same high-quality performance as their larger counterparts but are perfect for limited space or budget constraints.

4. Vulcanization Autoclaves

Vulcanization autoclaves are used specifically for curing rubber. The autoclave vulcanization rubber process involves heating rubber in the presence of sulfur to improve its elasticity and strength, making the end product more durable. This type of autoclave is used in tire production, industrial seals, and various other rubber products. As with composite materials, ensuring the rubber is free of defects is critical, making the role of these autoclaves indispensable in rubber manufacturing.

Choosing the Right Autoclave

When choosing an autoclave, it's essential to consider the specific requirements of your industry and applications. For instance, if you're in the composite materials sector, looking at composite autoclave suppliers with a proven track record is crucial. ETSA offers a range of autoclaves that cater to different needs, from large industrial units to more small composite autoclave setups. Their diversified portfolio ensures you'll find the perfect equipment tailored to your specific application.

Conclusion

The world of autoclaves is more diverse than many people realize. From medical settings to industrial applications, the type of autoclave you need will vary based on your operational requirements. Medical autoclaves focus on sterilization, industrial autoclaves cater to various large-scale processes, composite autoclaves handle high-performance materials like carbon fiber, and vulcanization autoclaves specialize in rubber curing.

Whether you are looking for a specialized carbon fiber autoclave for sale or require a smaller composite autoclave for niche productions, understanding your needs and the capabilities of each type of autoclave is crucial. Trusted brands like ETSA provide a range of options, ensuring high quality and reliability. For manufacturers and industries looking to enhance their production processes, investing in the right autoclave can make a significant difference.

One thing is clear: with the right autoclave, whether you're sterilizing medical instruments or curing advanced composite materials, you can achieve unparalleled precision, quality, and efficiency. So, take the time to understand your needs and choose wisely from reputable composite autoclave suppliers. You'll find that the right investment pays off in manifold ways.

If you have any specific needs or queries regarding autoclaves, don’t hesitate to contact ETSA or other reputable composite autoclave suppliers for expert advice and top-quality products.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China