Composite autoclaves play a pivotal role in the intricate process of shaping carbon fiber composite materials, offering a multitude of advantages in terms of efficiency and versatility. Delving into the complexities of the composite autoclave, we explore its principles, evolution, and the crucial equipment involved in this advanced manufacturing process.

Crafting with Precision: Process Principles of Composite Autoclave

The process involves meticulously layering carbon fiber prepreg materials onto molds, sealing the blank in a vacuum bag, and placing it inside the composite autoclave. Operating under vacuum conditions, the autoclave undergoes a series of temperature and pressure cycles, uniformly curing the material. This meticulous process results in the creation of high-quality, intricately shaped carbon fiber composite components with superior surface and internal quality.

Evolution of the Process: Composite Autoclave Development

The composite autoclave process, developed specifically for second-generation composite material production, emerged in the 1940s. It gradually gained widespread usage, finding applications in aerospace, electronics, weaponry, transportation, sports equipment, and emerging energy technologies. Its significance in producing various skin components, especially in aerospace, has made it a mature and widely adopted manufacturing process. Today, the composite autoclave process stands as one of the primary methods for shaping carbon fiber composite components, extensively utilized by manufacturers.

Key Equipment Components: Powering the Composite Autoclave Process

Composite Autoclave

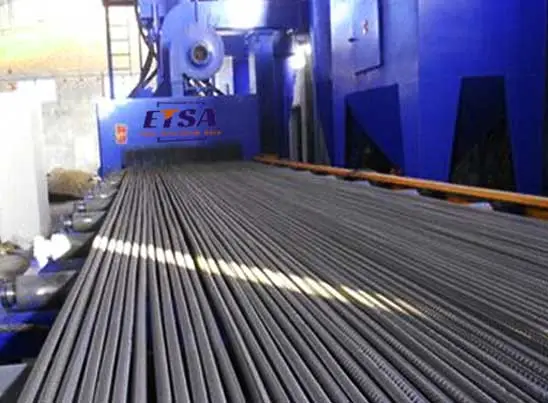

As one of leading autoclave machine suppliers, ETSA autoclave is a specialized piece of equipment tailored to the characteristics of polymer-based composite material molding. Known for its high precision in temperature and pressure control, structural reliability, system stability, low energy consumption, and user-friendly operation and maintenance, the autoclave facilitates modular and serialized production. This makes it adaptable to diverse fields, processes, and specifications.

Equipment Composition

Overall Structure: Comprising the autoclave body, door mechanism, high-temperature motor, and insulating layer, forming a pressure-resistant and high-temperature vessel.

Safety Interlock Device: Comprising automatic pressure interlocks, manual interlocks, and ultra-high-pressure alarm devices.

Quick Open Door Device: Featuring a design allowing manual or electrically assisted quick opening, ensuring normal door operation during power outages.

Sealing Device: Implementing a silicon rubber inflatable seal for high-pressure resistance.

Pressure System: Including a compressor, air storage tank, pressure control valve, pipelines, pressure transmitter, and pressure gauge, maintaining precise internal pressures of 1.5-2.5MPa with minimal error.

Heating System: Comprising stainless steel electric heating tubes, high-temperature fans, air ducts, insulating layers, and a temperature control system. The heating power meets the maximum temperature requirements and heating rate demands.

Temperature Circulation System: Featuring a circulation fan, guide plates, and baffles to accelerate heat conduction and circulation, establishing a uniform temperature field.

Vacuum System: Comprising a vacuum pump, pipelines, vacuum gauge, and vacuum valve, creating vacuum conditions for prefabricated composite materials, with multiple vacuum tube joints meeting molding process requirements.

Automatic Control System: Utilizing a PLC control system, ensuring high-precision control and real-time recording of pressure, temperature, cooling, and other process parameters throughout the entire process.

In conclusion, the composite autoclave stands as a cornerstone in the production of carbon fiber composite components, epitomizing precision, efficiency, and adaptability in manufacturing processes. Its evolution from a specialized process to a widely embraced technology underscores its crucial role in shaping the future of composite material manufacturing.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China