With the rapid development of aerospace technology, the demand for materials' performance and manufacturing processes continues to rise. The small composite autoclave, as an advanced processing equipment, plays an increasingly important role in the aerospace industry. This article will explore the innovative applications of small composite autoclaves in the aerospace industry.

Technical Advantages of Small Composite Autoclaves

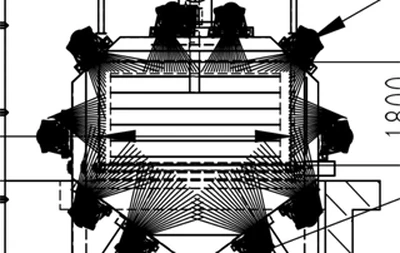

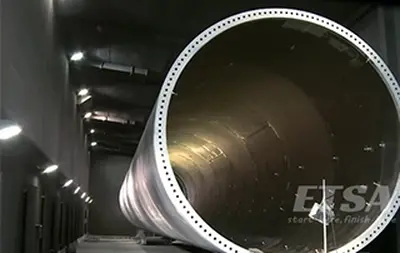

With its unique technical advantages, small composite autoclaves bring revolutionary changes to the aerospace industry. Its compact design and efficient performance make the curing process of composite materials in high-pressure and high-temperature environments more precise and controllable. Additionally, small composite autoclaves feature high levels of automation and intelligence, significantly improving production efficiency and reducing production costs.

Application in Aerospace Structural Materials

The application of small composite autoclave in aerospace structural materials is particularly prominent. Aerospace vehicles require materials that are lightweight, high-strength, corrosion-resistant, and fatigue-resistant. Composite materials are the ideal choice to meet these requirements. Composite materials cured with small composite autoclaves not only possess excellent mechanical properties but they can also achieve precise manufacturing of complex shapes and structures. This ensures that aerospace vehicles can maintain light weight while having higher structural strength and stability.

Application in Aerospace Engine Manufacturing

The small composite material autoclave also plays a crucial role in aerospace engine manufacturing. The engine is a core component of aerospace vehicles, and it demands exceptionally high standards for material performance and manufacturing processes. The small composite material autoclave can precisely control the curing process of composites under high pressure and high temperature, resulting in engine components with outstanding performance. These components not only exhibit characteristics like light weight and high strength but also withstand extreme working conditions such as high temperatures and pressures, providing robust support for the reliability and durability of aerospace vehicles.

Future Outlook and Challenges

With the continuous advancement of aerospace technology, the demands on composite materials and their manufacturing processes are also increasing. As an advanced processing equipment, the small composite material autoclave will face more opportunities and challenges. In the future, it will need to continuously improve its technological capabilities to meet the higher requirements of the aerospace industry for material performance and manufacturing processes. At the same time, it must strengthen integration and innovation with other advanced technologies to drive the ongoing development of the aerospace industry.

In summary, the small composite material autoclave holds broad application prospects and significant strategic importance in the aerospace industry. With technological advancements and expanding application scenarios, it will play an increasingly important role in the aerospace sector. If you want to get more information about this small composite material autoclave. Just be free to contact us. ETSA, as one of trusted and professional autoclave machine suppliers, will be your first choice!

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China