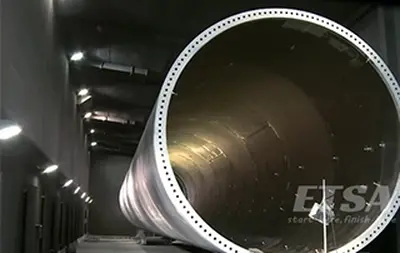

When designing dust removal for a sandblasting container, we need to pay special attention to the following three matters, as they are crucial to the dust removal effectiveness of the sandblasting container:

Three Common Abrasives and Their Dust Amounts

The abrasives we commonly use fall into three categories: steel shot, yellow sand, and brown corundum.

The amount of dust generated by these three types of abrasives during blasting is different. Steel shot produces the least dust, yellow sand produces the most, and brown corundum is in the middle. Due to the differing dust amounts, the equipment and airflow required for the same volume varies.

Two Methods to Calculate Airflow in Sandblasting Containers

Therefore, there are two ways to calculate the airflow for a sandblasting container:

Air Change Rate, which means estimating or calculating by a formula the number of times the air needs to be changed per minute based on the dust concentration of the entire sandblasting container's volume. This way, we can determine the air change rate and the total airflow.

For example, for yellow sand, the air change rate is about 150 to 200 times per hour, for steel shot it is about 120 to 150 times per hour, and for brown corundum, it is usually around 150 times. This is done using the air change rate method.

Calculating based on the cross-sectional area ensures the dust absorption inside the sandblasting container to determine the airflow. By using the cross-sectional area, we ensure that the dust doesn't need an excessive negative pressure. The primary goal is to prevent dust from escaping outside the door. It only needs a certain negative pressure to allow the dust to naturally settle inside the sandblasting container or be exhausted through the extraction vent to the outside into the dust collector for filtration.

We usually calculate the cross-sectional area as length * height. Using this cross-sectional area, we can apply our standard calculation formulas. However, attention must be paid to the selection of the filtration wind speed, which we can set to as low as 0.2 or 0.3, thus ensuring that the airflow remains within a reasonable range.

Considerations for Selecting Air Makeup Vents

Here are some considerations for selecting air makeup vents. The size of the air makeup vent is regulated; it should not be too small. If it's too small, the air inside won't be sufficiently refreshed, resulting in poor exhaust efficiency inside.

If the air makeup vent is too large, it can cause dust to escape outside. The air makeup vent's size needs to be calculated. If using an axial fan to supplement air for the sandblasting container, we must be mindful of the airflow direction to avoid causing dust to rotate inside the room, which would hinder its removal.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China