In the realm of industrial advancements, automated sandblasting equipment has emerged as a versatile solution, finding widespread use. Beyond the obvious benefits of saving manual labor, these machines contribute to increased efficiency, elevating production schedules. Let's delve into the intricacies of the working principle of automated sandblasting rooms, exploring their functionalities and the impact they bring to industrial processes.

Sandblasting Room Automation: Enhancing Efficiency

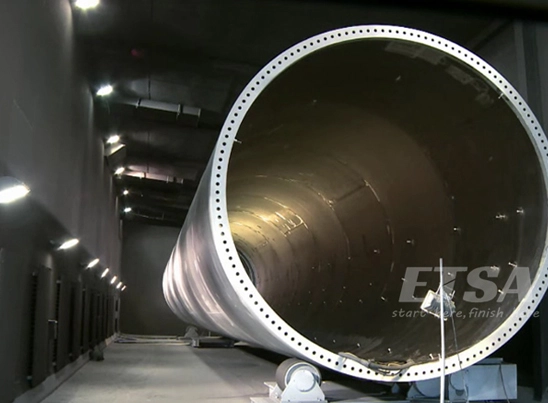

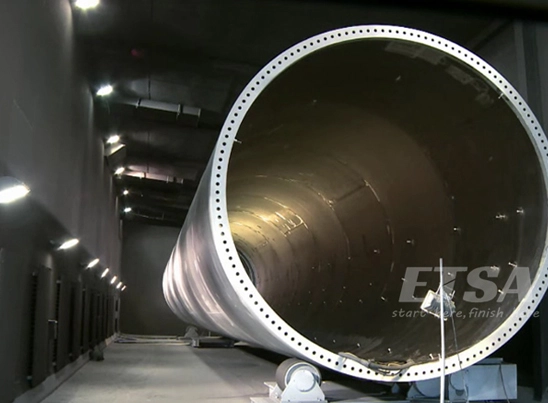

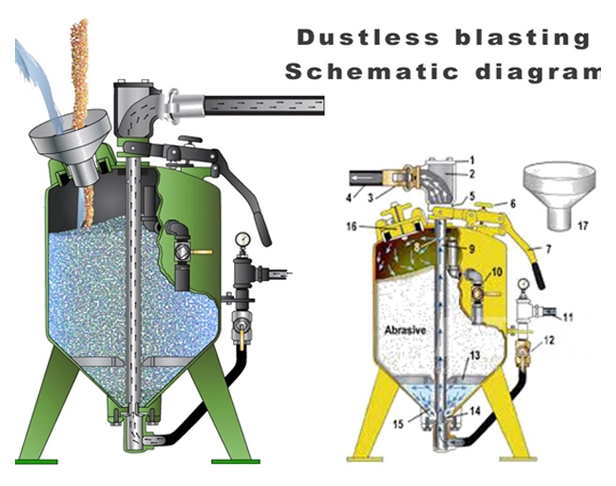

Automated sandblasting rooms are designed not only to treat the surfaces of workpieces but also to seamlessly automate various processes, ranging from workpiece entry and exit to the automatic oscillation of sandblasting guns and the classification of abrasives. By incorporating a triangular belt conveyor system, these machines eliminate sand accumulation, providing variable belt speeds to cater to different sandblasting process requirements through frequency modulation.

Workflow of an Automated Sandblasting Room

The working process of an automated sandblasting room follows a systematic sequence. The conveyor belt transports the products into the sandblasting chamber. Once the sandblasting is complete, the products are directed into the blowing chamber for an automated cleaning process. The automated system then removes the products from the conveyor belt, ready for manual retrieval. This entire sequence unfolds automatically and continuously, enabling the completion of the production process without manual intervention.

Users have the flexibility to tailor the operation process based on the specific needs of their factory. In this scenario, the entire production process unfolds without the need for manual operations, showcasing the true potential of automation in industrial settings.

Customization for Diverse Requirements

Automated sandblasting rooms can be equipped with multiple sandblasting guns, offering customization based on customer needs and specific industrial processes. During production, workpieces can be placed directly on the conveyor belt or mounted on fixtures, moving at a consistent speed through the sandblasting chamber. Motor-driven sandblasting guns oscillate through a swinging mechanism, ensuring uniform sandblasting of the processed surface. Once the treatment is complete, the workpiece is blown clean using compressed air guns, removing any residual sand. The finished product exits from the other end of the conveyor line.

Adaptive and Efficient Operation

The flexibility of automated sandblasting machines is noteworthy, allowing for the adjustment of each gun's angle and enabling precision sandblasting. The inclusion of a cyclone separation system enhances dust removal efficiency, ensuring a clean working environment. This, coupled with high sandblasting efficiency, makes automated sandblasting rooms a preferred choice for industrial applications.

In conclusion, the working principle of automated sandblasting rooms epitomizes efficiency and precision in industrial surface treatment. As industries continue to embrace technological advancements, these automated solutions prove instrumental in achieving higher production standards while adhering to complex manufacturing requirements. The synergy of automated sandblasting rooms with cutting-edge technologies reflects the evolution of industrial processes towards a future characterized by innovation, efficiency, and environmental consciousness.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China