In the steel bar manufacturing industry, surface treatment of steel is a crucial step. As an important equipment in this process, the rebar shot blasting machine not only significantly improves production efficiency but also provides strong support for enhancing the quality of steel bars. This article will explore the application and value of the rebar shot blasting machine in the steel bar manufacturing industry from four aspects.

Increase Production Efficiency

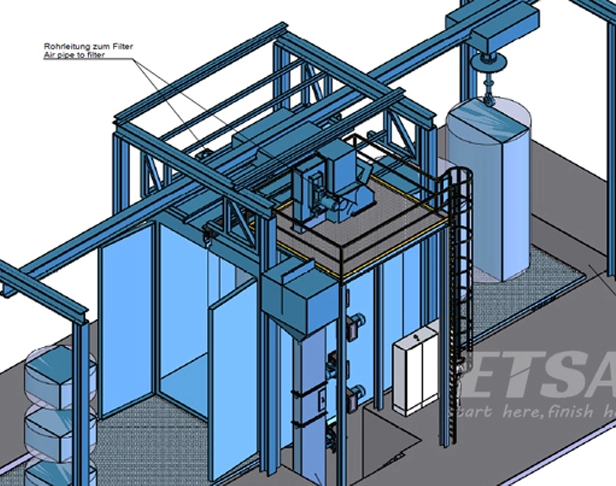

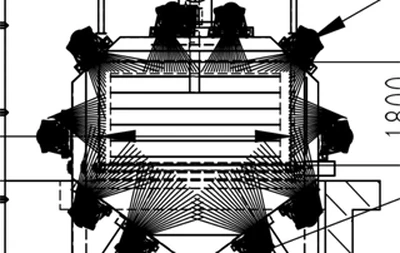

The rebar shot blasting machine uses a high-speed rotating shot blaster to shoot steel shots at a very high speed onto the surface of the steel bar, effectively removing rust, oil stains, and other impurities, making the surface smooth and clean. Compared to traditional manual rust removal or chemical rust removal methods, the rebar shot blasting machine not only works with higher efficiency but also can handle large areas of rebar at once, significantly increasing production efficiency.

Improve Rebar Quality

Surface rust and oil stains on rebar not only affect aesthetics but also negatively impact the strength and durability of the rebar. The rebar shot blasting machine can thoroughly remove these impurities, restoring the original metallic luster of the rebar and enhancing its strength and durability. Additionally, during the shot blasting process, the impact of the steel shots can eliminate residual stress and micro-cracks in the rebar, further improving its quality.

Reducing Production Costs

The application of rebar shot blasting machines not only enhances production efficiency and rebar quality but also reduces production costs. On one hand, the high efficiency of shot blasting machines significantly decreases the time and labor costs associated with manual rust removal. On the other hand, the steel shots used in the blasting process are reusable, which lowers material costs. Additionally, since shot blasting machines can handle large areas of rebar in one go, they reduce transportation and storage costs during the production process.

Environmental Protection and Energy Efficiency

With increasing environmental awareness, traditional chemical rust removal methods are gradually being phased out. As a physical rust removal method, the rebar shot blasting machine does not produce harmful chemicals and effectively controls dust emissions. Furthermore, the energy consumption of shot blasting machine is relatively low during operation, aligning with the trends of energy conservation and environmental protection.

In summary, the application of rebar shot blasting machines in the rebar manufacturing industry holds significant value. It not only improves production efficiency, enhances rebar quality, and reduces production costs but also offers environmental and energy-saving benefits. As technology continues to advance and market demand expands, the application prospects for rebar shot blasting machines in the rebar manufacturing industry will become even more promising.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China