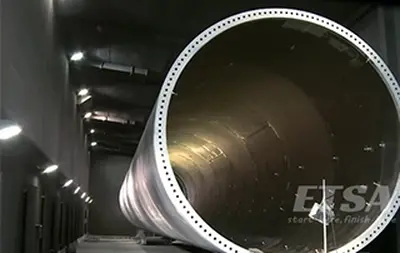

The equipment of shot blasting cleaning machine is mainly composed of shot blasting machine, wear-resistant rubber belt, stranding machine, lifting machine, separator, feed conveying machine, duster and cleaning machine.

Dust removal is to remove dust from the air in the cleaning room and other devices to prevent pollution to the atmosphere.

The dust removal equipment can be divided into coarse purification, medium purification and fine purification according to the size of dust particles. The coarse purification is to capture dust particles larger than 100 microns. The medium purification is to capture dust particles of 10-100 microns and the fine purification is to capture dust particles of 10 microns.

The efficiency of dust removal can be improved obviously by increasing the level of dust removal in the ventilating and dusting device, but the general dusting system only adopts two-stage dusting. With the least dust cleaning work only choose a fine purification filter.

The role of the precipitator is basically the same as that of the volumetric separator, but simpler in construction. Its main effect is to make the airflow in the indirect flow out of time, the coarse particles in the airflow precipitation down, in order to reduce the second, the third level of dust removal purification of the burden of the dust collector.

The precipitator is used for coarse purification, the secondary dust removal is used for medium purification, and the third level dust removal is used for fine purification.

The second level of dust removal generally adopts CLT/ A-type cyclone dust collector, whose dust removal efficiency is 70-90. When dealing with large air volume, A large diameter cyclone dust collector is needed, but then the dust removal efficiency will be reduced. In order to maintain A high dust removal efficiency, A bipolar cyclone dust collector with concentrator can be selected, whose dust removal efficiency is 85-90.

The third grade dust collector generally adopts LDM pulse back - blowing bag dust collector. When the bag is cleared of dust, the dust collector can do non-stop wind back blowing dust. Its dedusting efficiency is 90, there is a flat bag cylindrical rotary back blowing dust collector, its single capacity is large, can make the piping system simple, less occupation, especially suitable for large air volume, high negative pressure ventilation and dust removal device. In addition, the wet self-excited dust collector can be selected, and its dust removal efficiency is 98-99.

Finally, the transportation and disposal of ash should be solved. Wet dust removal to solve the problem of sludge treatment and sewage treatment, in the northern region there are also to solve the problem of anti-freezing, sewage treatment equipment is also relatively large.

In the ventilating and dusting equipment, it is usually necessary to use a high-pressure centrifugal ventilator. The exhaust noise and mechanical noise generated by the high-pressure centrifugal ventilator will cause harsh working environment. For this reason, a silencer can be installed on the exhaust spring of the ventilator to reduce the exhaust noise. In order to reduce mechanical noise, the ventilator can be placed in the ventilator room with sound insulation, or to the ventilator housing with sound insulation.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China