The rotary table shot blasting machine for sale is a highly efficient and versatile equipment used in industrial surface preparation. It is widely used for cleaning, descaling, deburring, and enhancing the surface finish of various components. This machine’s design and functionality offer several advantages, making it a preferred choice in industries like automotive, aerospace, and metalworking. In this article, we will explore the key benefits of using a rotary table shot blasting machine for sale.

Rotary Table Shot Blasting Machine High Efficiency and Consistency

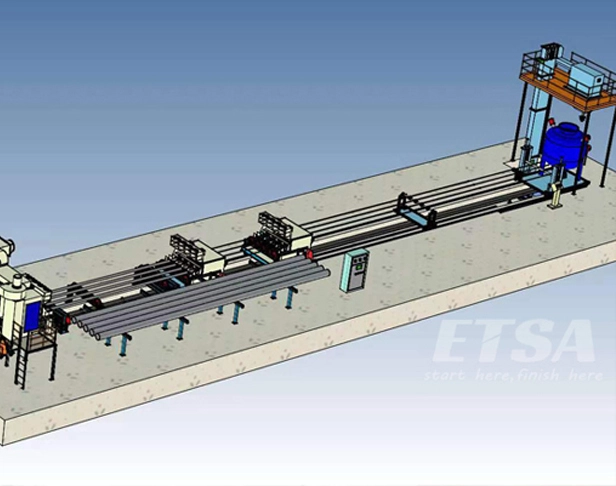

One of the most significant advantages of the rotary table shot blasting machine for sale is its ability to provide high-efficiency surface cleaning and preparation. The rotary table design ensures that components are exposed to the blast stream evenly as they rotate, leading to consistent cleaning and surface treatment.

This consistent exposure to shot blasting ensures:

1. Uniformity in the cleaning process

2. Reduction in operator errors

3. Faster processing times compared to traditional methods

| Feature | Benefit |

|---|

| Rotary Table Design | Even exposure to the blasting stream |

| Consistent Results | Higher surface quality and uniformity |

| Increased Efficiency | Reduced cycle times |

The rotary table shot blasting machine for sale is ideal for industries that require quick turnaround times and high-quality surface finishes.

Versatility in Applications of Rotary Table Shot Blasting Machine

The rotary table shot blasting machine for sale is incredibly versatile and can handle a wide variety of components, including small to medium-sized parts. From automotive parts like gears, brackets, and castings to industrial components used in manufacturing processes, this machine can handle different shapes and sizes with ease.

Some typical applications include:

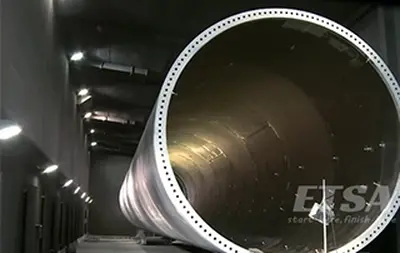

1. Cleaning of metal castings and forging parts

2. Deburring of mechanical parts

3. Surface hardening and preparation for coatings

This versatility makes the rotary table shot blasting machine for sale a go-to solution for many industrial sectors.

Rotary Table Shot Blasting Machine Improves Durability and Reduced Wear

The rotary table shot blasting machine for sale offers enhanced durability over time, thanks to its robust construction and superior blasting components. The machine is designed to withstand the wear and tear of continuous operation, making it suitable for high-demand environments.

Key factors that contribute to its durability:

1. High-quality materials used in construction

2. Efficient and easily replaceable wear parts

3. Advanced control systems for smooth operation

By maintaining optimal performance over extended periods, the wholesale shot blasting machine for sale ensures cost-effectiveness and longevity.

Low Maintenance and Easy Operation of Rotary Table Shot Blasting Machine

Another notable advantage of the rotary table shot blasting machine for sale is its low maintenance and user-friendly operation. The machine is designed with intuitive controls that simplify the operator's job. With proper care, the machine requires minimal downtime for maintenance and is built to function with a high level of reliability.

Maintenance features include:

1. Easy access to internal components for cleaning and repair

2. Self-lubricating systems that reduce friction and wear

3. Automated monitoring systems to detect issues early

These features ensure that the rotary table shot blasting machine for sale runs efficiently with reduced manual intervention and operational costs.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China