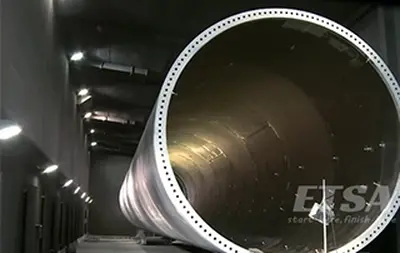

The pipe sandblasting machine is an essential tool in industrial surface preparation, especially for cleaning, derusting, and roughening the exterior or interior surfaces of pipes. However, for safe and efficient operation, there are several key precautions that operators and engineers must follow. Understanding these precautions helps maximize productivity, reduce wear, and ensure the long-term reliability of the equipment.

Ensure Proper Operator Training

Before using a pipe sandblasting machine, all personnel involved must be properly trained in machine operation, safety protocols, and emergency response procedures. The machine operates under high pressure and involves abrasive materials, so mishandling may lead to injury or equipment damage.

Key training topics include:

Operating sequence and shutdown procedures

Personal protective equipment (PPE) requirements

Emergency stop and safety interlock functions

| Required PPE for Operation | Purpose |

|---|

| Blast helmet with air supply | Protects face and lungs |

| Protective gloves and coveralls | Shields skin from abrasives |

| Hearing protection | Reduces exposure to noise |

Proper training ensures that the pipe sandblasting machine is operated safely and efficiently.

Conduct Regular Equipment Inspections

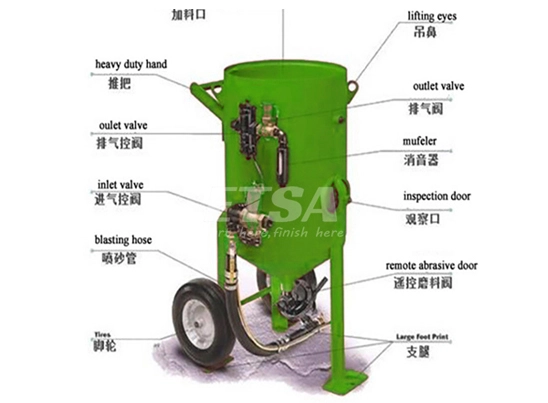

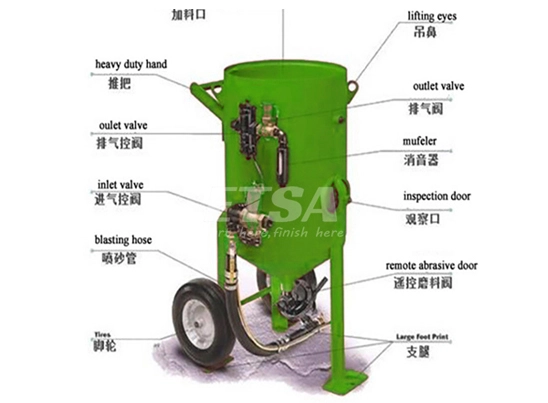

Routine inspection of the pipe sandblasting machine is critical to maintaining performance and avoiding unplanned downtime. Operators should check all moving parts, blast nozzles, hoses, and valves for wear, leaks, or blockages.

Particular attention should be given to:

Nozzle wear and alignment

Abrasive delivery system condition

Dust collection system operation

By performing daily and weekly checks, potential issues can be identified early, preventing costly breakdowns or safety hazards.

Monitor Abrasive Material and Dust Collection

The choice and management of abrasive material directly affect the performance of the pipe sandblasting machine. Ensure that the correct abrasive type (e.g., steel grit, garnet, aluminum oxide) is used according to the material of the pipe and the desired finish.

Additionally, dust generated during sandblasting must be efficiently captured. Poor dust collection can reduce visibility, pose health risks, and decrease machine efficiency.

| Abrasive Type | Best Use Case |

|---|

| Steel grit | Heavy-duty rust and scale removal |

| Garnet | Precision blasting with lower surface damage |

| Aluminum oxide | Non-ferrous pipe materials |

Always monitor abrasive flow and maintain the dust collector to keep the pipe sandblasting machine running cleanly and safely.

Follow Safe Start-Up and Shutdown Procedures

Correct startup and shutdown procedures are vital for protecting both the operator and the pipe sandblasting machine. During startup, ensure that all components are in place, the blast cabinet is sealed, and safety systems are activated.

When shutting down, avoid abruptly stopping the system. Follow the manufacturer’s recommended steps, including:

Turning off the blast generator

Draining residual abrasives

Cleaning filters and blast area

Improper shutdown may lead to clogged components, excessive wear, or residual pressure buildup that could be dangerous during the next operation.

The pipe sandblasting machine is a powerful and effective tool for industrial steel pipe shot blasting machine. However, to fully leverage its capabilities and ensure safe operation, users must follow clear precautions—from training and inspection to material monitoring and shutdown procedures.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China