1. Size range of composite autoclave

Composite autoclaves are important high-temperature and high-pressure process equipment commonly used in industries such as powder metallurgy, hot isostatic pressing, high-temperature and high-pressure chemical reactions. Its size not only directly affects production efficiency and finished product quality, but also determines production costs and investment scale.

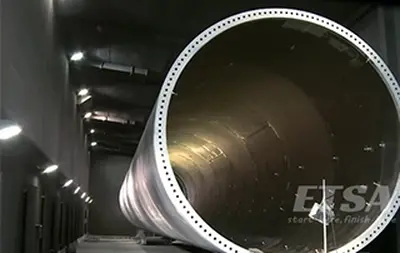

Generally speaking, the size specifications of composite autoclave will be selected based on their actual use. The size of carbon fiber composite autoclave can be customized according to customer requirements, ranging from a diameter of 400mm to 4500mm.

2. Select according to process requirements

The selection of composite autoclave needs to consider their process requirements, such as working temperature, working pressure, and working medium. At present, there are various types of hot press tanks on the market, including medium hot press tanks and non medium composite autoclave. Therefore, when selecting a composite autoclave, it is necessary to conduct rigorous screening according to the process requirements.

3. Select according to production needs

Production demand is another important factor to consider when choosing a composite autoclave. The first thing to consider is the characteristics of the production process, such as production scale, product types, production cycle, etc. Secondly, it is necessary to consider the actual usage of the equipment, such as its frequency of use and maintenance difficulty. By analyzing these demand factors and selecting a suitable composite autoclave scheme, the expected target effect can be achieved.

The above is a basic introduction to the size range and selection suggestions of composite autoclave, hoping to provide some reference and assistance for users of hot press cans. When selecting a composite autoclave, it is necessary to conduct rigorous screening based on the actual situation to ensure that the equipment can perfectly meet production requirements and bring better economic benefits. ETSA, one of reliable and professional autoclave machine manufacturers in China, will be your first choice! Competitive autoclave machine price and one-stop service! Contact us to quote.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China