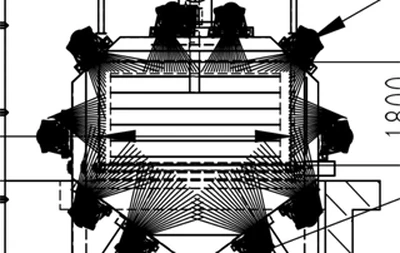

The demand for lightweight, high-strength materials has transformed industries ranging from aerospace to sports equipment. At the heart of many composite production lines lies the carbon fiber autoclave, a specialized pressure vessel used to cure carbon fiber components under precisely controlled temperature and pressure conditions. The following outlines the core applications of the carbon fiber autoclave and why it remains essential in advanced manufacturing.

Aerospace and Aviation: Precision Under Pressure

In aerospace engineering, safety and performance depend heavily on the integrity of each component. The carbon fiber autoclave is widely used in the aerospace sector to produce structural elements such as fuselage panels, wing components, fairings, and brackets. Autoclave processing ensures minimal void content and consistent material density—both critical for flight-worthy parts.

| Aerospace Components | Key Requirements Met by Autoclave |

|---|

| Fuselage skins | High strength-to-weight ratio |

| Wing structures | Fatigue and impact resistance |

| Engine nacelles | Thermal stability and durability |

By using a carbon fiber autoclave, aerospace manufacturers achieve not only regulatory compliance but also competitive performance metrics.

Automotive Industry: Lightweight Innovation

As electric and high-performance vehicles continue to evolve, reducing weight without compromising safety is a top priority. The carbon fiber autoclave by the leading composite autoclave suppliers is used to manufacture critical automotive parts like chassis frames, body panels, and suspension components. The autoclave curing process enables superior bonding and fiber alignment, enhancing crashworthiness and fuel efficiency.

This approach is increasingly applied in:

Racing and supercar production

Electric vehicle battery enclosures

Carbon-fiber-reinforced hoods and roofs

For automakers, the carbon fiber autoclave offers the precision and repeatability needed for both prototyping and scaled production.

Sports and Recreation: High Performance with Lightweight Design

The sports equipment industry relies on the carbon fiber autoclave to produce gear that demands both performance and durability. Bicycles, tennis rackets, paddles, skis, and racing helmets benefit from autoclave processing, which ensures a flawless surface finish and optimized fiber volume content.

Key benefits include:

Enhanced structural integrity

Reduced weight for improved handling

Custom shapes and design flexibility

High-end consumer sports products are now often indistinguishable from aerospace-grade composites—thanks to the precise manufacturing enabled by the carbon fiber autoclave. Learn more about the carbon fiber autoclave price now!

Wind Energy, Medical, and Industrial Applications

Beyond transport and recreation, the carbon fiber autoclave plays a vital role in producing parts for wind turbines, medical imaging devices, and pressure vessels. In wind energy, blade sections and nacelle components benefit from autoclave curing for maximum strength and aerodynamic stability. In medical fields, MRI bed structures and carbon-fiber brackets require non-magnetic, precise composite materials.

| Industry | Typical Components Made in Autoclave |

|---|

| Wind Energy | Blade spars, nacelle shells |

| Medical Equipment | Imaging table frames, supports |

| Industrial Use | Pressure vessels, robotic arms |

As demand grows for strong, corrosion-resistant, and lightweight components across sectors, the carbon fiber autoclave remains a critical tool for high-performance manufacturing.

The carbon fiber autoclave is more than just an industrial oven—it is a gateway to engineering excellence. Its precision curing capabilities enable the production of high-strength, lightweight composites used in aerospace, automotive, sports, energy, and medical industries. As innovation accelerates, the role of the carbon fiber autoclave will continue to expand, powering the next generation of composite applications with reliability and accuracy.

Call us on:

Call us on:  Email Us:

Email Us:  No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China

No. 3213 Lingshanwan Road, Huangdao District, Qingdao City, China